Handling days are when small equipment weaknesses become expensive problems: a kick, a crushed hand, a missed dose, or an animal that learns to fight the system. A quality livestock crush turns “wrestling” into a repeatable process with secure restraint and calmer cattle. It also provides safer access for routine jobs like vaccinating, ear tagging, weighing, and basic vet work.

In this guide, you’ll get ten practical reasons to invest, a selection checklist for comparing cattle crushes, and setup tips that improve flow from pen to race. That’s how you ensure that your team stays safe and efficient every time.

What Is a Cattle Crush and How It’s Different From a Chute Headgate and Race

What is a cattle crush? It’s a restraint unit that holds cattle still for safe examination, identification, weighing, and treatment, minimising injury risk to you.

Where the Crush Fits in the Handling System

In a yard, cattle move direction: holding pen to the forcing (crowd) pen, into a race (alley), then into the cattle handling crush, a crush for cattle. This flow keeps animals moving, lets you work safely at the restraint point, and releases them to a dispersal pen.

Quick Terminology Map UK, AU vs US

In the UK/Australia/NZ, “cattle crush” commonly means the restraining unit for cattle. In North America, you’ll hear “squeeze chute” or “cattle chute” for the same equipment. “Headgate” is the front catching mechanism, and “race” (alley) is the lane that feeds cattle into it. It’s a crush for livestock on farms.

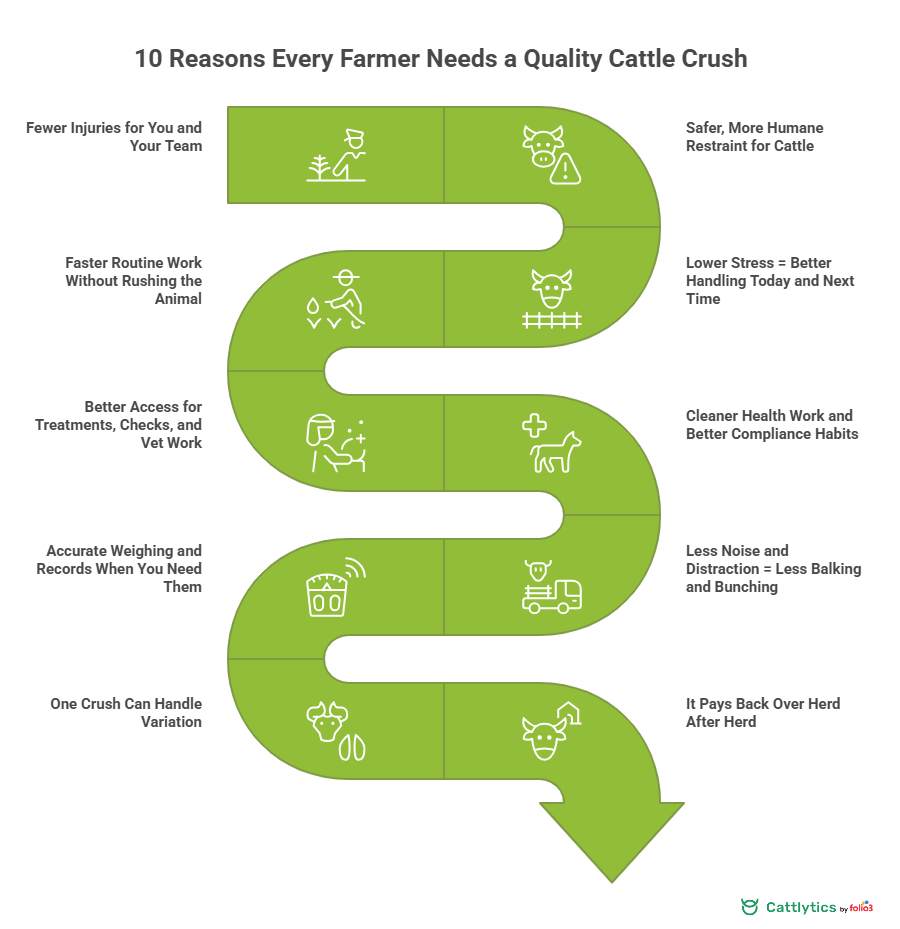

The 10 Reasons Every Farmer Needs a Quality Cattle Crush

Discover how the right cattle crush improves safety, animal welfare, workflow efficiency, treatment accuracy, and long-term handling success across everyday livestock operations on your farm.

1) Fewer Injuries for You and Your Team

Handling injuries happens in seconds; a quality cattle crush reduces kicks, pinch points, and last-minute improvisation. It standardizes where you stand and where the gates move, every time. What to look for:

- Flush latches and protected hinges

- Predictable side-operated release you can reach under pressure

- Smooth panels with minimal protrusions

Real-world use case: Vaccinating and tagging becomes two-person work instead of a wrestling match, calmly.

2) Safer, More Humane Restraint for Cattle

Why it matters: When a restraint fits the animal properly, you reduce bruising, panic, and unnecessary pressure for better welfare and easier procedures. What to look for:

- Adjustable head yoke/headgate that holds without choking

- Side squeeze or panel design that applies even, controlled pressure

- Non-slip flooring and solid sides to prevent flailing

Real-world use case: Pregnancy checking or injections stay smooth because the cow stands quietly, not fighting the crush.

3) Lower Stress = Better Handling Today and Next Time

Stress makes cattle balk, rush, and remember bad experiences; lower stress improves repeat handling and reduces risk. What to look for:

- Solid-sided race into the cattle handling crush to block distractions

- Lighting and reduced shadows at the entrance

- Curved or aligned flow that keeps cattle moving forward

Real-world use case: Next processing day, cattle walk into the crush for cattle instead of turning back.

4) Faster Routine Work Without Rushing the Animal

Extra minutes in the race raise stress, labor, and error risk; a good cattle crush lets you process cattle consistently at your pace. What to look for:

- Quick-catch headgate and easy controls operated from the side

- Smooth gates that reset fast between animals

- Clear work zones so two people can work without crossing paths

Real-world use case: Drenching a group becomes flow, not stop-start chaos.

5) Better Access for Treatments, Checks, and Vet Work

Safe access means you do the job right, no rushed injections, missed tags, or risky leaning on tight handling days. What to look for:

- Side access doors or split vet gates for 360 access

- Rear gate or rump bar to stop backing up

- Palpation access if you pregnancy test or AI

Real-world use case: Your vet works from the rear while you control the head.

6) Cleaner Health Work and Better Compliance Habits

Clean, controlled processing helps you follow protocols like right dose, right animal, right record without cutting corners. What to look for:

- Non-slip, easy-clean footing and drainage around the cattle crush

- Good lighting so you can read tags, syringes, and injection sites

- Safe work area (catwalk/clear stance) so staff keep hands out of danger

Real-world use case: You can run a consistent vaccination SOP even with new workers.

7) Less Noise and Distraction = Less Balking and Bunching

Noise, flapping chains, and visual distractions trigger balking and bunching, which turns one nervous animal into ten. What to look for:

- Solid panels on the approach to the cattle handling crush

- Quiet, well-fitted gates that don’t bang or rattle

- A tidy entry: remove loose ropes, dangling chains, and sharp contrasts

Real-world use case: Cattle step forward instead of jamming the race at the entrance.

8) Accurate Weighing and Records When You Need Them

Accurate weighing and ID help you decide confidently on feeding, culling, and breeding based on data, not memory. What to look for:

- Crushes designed to integrate with load bars/weigh heads

- Space to mount an EID reader or tag panel where cattle pause naturally

- Stable restraint that prevents shifting while weighing

Real-world use case: You capture weights at processing and adjust ration or sale timing quickly.

9) One Crush Can Handle Variation

Your herd isn’t one size; cows, bulls, and youngstock need secure restraint without excess pressure or escape gaps across the season. What to look for:

- Adjustable width/side squeeze to match body size

- Headgate/yoke settings that accommodate different neck sizes

- Optional calf module or separate calf crush if you process many small calves

Real-world use case: One setup handles weaners today and mature cows tomorrow, safely.

10) It Pays Back Over Herd After Herd

A cattle crush pays back through time saved, fewer helpers, and fewer handling incidents. Especially on busy processing days. What to look for:

- Heavy-duty construction and parts you can service locally

- Controls that one trained operator can run smoothly

- Features matched to your workload (manual vs hydraulic vs specialist)

Real-world use case: Processing 30 heads takes less labor and less downtime, season after season.

How to Choose the Right Crush for Livestock Without Overbuying

Learn how to match crush type, features, and layout to your herd size, handling frequency, and budget, so you invest once, correctly, and avoid costly mistakes.

Step 1 — Match Crush Type to Use Case

Start with workload. Manual cattle crushes suit low-volume jobs and tighter budgets, but they demand good technique. Hydraulic units reduce effort and keep throughput steady when you process often. A specialist designs a suit for frequent vet procedures or hoof work. Pick the cattle handling crush that fits herd size, frequency, operator confidence, and solo operation, especially on busy days in your yards.

Step 2 — Fixed vs Mobile and When Hiring Makes Sense

A fixed crush for cattle is best when you run processing days and want a consistent, safe work zone. Mobile cattle crushes help if you manage multiple paddocks or leased ground. If you only need a crush a few times a year, hiring a contractor can reduce your upfront cost.

Step 3 — Feature Checklist That Actually Matters

Prioritize features that protect people and cattle:

- Head control plus emergency release, you can reach fast.

- Side access doors for treatments, checking, and vet work.

- Quiet, durable build with parts you can service and replace locally.

- Treat hydraulics, weighing mounts, and calf panels as only-if-you-do-X true add-ons.

Set-up Matters: A Great Crush in a Poor Layout Still Creates Chaos

A cattle crush can’t fix a poor approach. If cattle see people, dogs, or vehicles through open rails, they stop, turn back, and jam the race. Solid sides on the race and crowd pen reduce outside distractions and keep eyes forward.

Fix sightlines: remove flapping coats, dangling ropes, and sharp shadows at the entry, and add even lighting so the opening looks “safe” to step into. Then focus on you: work calmly, use steady pressure-and-release, and position yourself where cattle naturally move past you into the cattle handling crush. A catwalk keeps you clear and lets you work at the animal’s shoulder, not in front, so movement stays smooth today.

Pre-Use Checks and Basic Maintenance

Before every session, take three minutes to walk any cattle crushes from front to back.

- Check latches and catches lock securely, hinges swing freely, and every moving panel returns smoothly.

- Run your hand along edges to spot sharp metal, protruding bolts, or bent wire that can cut cattle or you.

- Look for cracked welds, loose pins, or broken boards, and clear mud or manure from pivot points and floors immediately.

Conclusion

A quality livestock crush improves safety, animal welfare, and handling-day efficiency by turning restraint into a repeatable system. If you want help choosing a crush for cattle or improving flow, we can share a handling-day audit checklist or do a quick crush-and-race layout review for your yards before you buy. So, consult with our experts at Cattlytics to shape your decision with proven insight.

FAQs

What Size Cattle Crush Do I Need For My Herd?

Choose a crush that fits your largest cows and bulls while adjusting down for smaller animals. Correct width, length, and headgate range prevent pressure injuries, escapes, and excessive animal movement.

Can One Cattle Crush Safely Handle Both Calves And Mature Cattle?

Yes, if it has adjustable side panels and head control. For high-volume calf work, a dedicated calf crush improves safety, control, and efficiency, especially during tagging, vaccination, and weaning procedures.

Is A Hydraulic Cattle Crush Worth It For Small And Mid-Size Farms?

Hydraulic crushes reduce operator effort, improve consistency, and enhance safety. They are worthwhile if you process cattle frequently, work alone, or want smoother control during pregnancy testing, AI, and health treatments.

What Safety Features Should A Modern Livestock Crush Always Include?

Essential features include secure head control, emergency release, anti-backing device, side access doors, non-slip flooring, quiet operation, and smooth latches to protect both handlers and cattle during restraint.

How Does A Livestock Crush Support Accurate Weighing And Performance Tracking?

Proper restraint keeps cattle still on the scales, improving weight accuracy and EID reads. This supports reliable growth monitoring, feed efficiency analysis, and marketing decisions based on trustworthy performance data.